Hey, it’s the weekend! Besides, I’m pretty much sick and tired of politics and need a break from both Republicans and Democrats. And “conservatives”. Especially conservatives. More on that later but for now, let’s smoke some pork ribs!

I’ve been barbecuing meat for a long, long time. I’m old, remember? I’ve had small grills, trailer mounted offset pits, Weber Smokey Mountain pit/grills, gas grills, and for the past three years, a Masterbuilt Electric Smoker. About a month ago, that smoker went kaput (I’m no electrician), so I had a choice – spend another $400 on another Masterbuilt or come up with something else.

I decided to go with a Pit Barrel Cooker because it seems to be all the rage on the bbq forums. So I ordered one online, a nice lady called me a few hours later, told me that they were backordered but that it should ship the following week. Okay, no problem. But then I noticed that they deducted the purchase from my bank account the same day I ordered it. Bad business practice. But I decided to wait it out.

In the meantime, it became clear to me that the “rage” about that cooker was because they had a good marketing plan. They gave away seemingly hundreds of the things to cookoff teams, bbq forum webmasters, and bbq website owners. Huh. So that’s why they charge so much for a product that costs them about $70 to make. Interesting. Now I’m having serious buyers remorse.

Another bbq forum “rage” is the Ugly Drum Smoker. Supposedly great taste, stable temperature, and my favorite part, cheap! After thinking it over for a week, I called the Pit Barrel Cooker Company and cancelled my order. After a couple of days, they credited my account and I had my $289 back. I don’t know if they are having cash flow problems or what but it is a bad, bad business practice to charge for something and then take your time shipping it.

So I went on Craigslist, found a clean, unlined open head drum, and made my own Ugly Drum Smoker. There are all kinds of them out there, just check this Google image search. Not all of them are so ugly!

I wanted to keep mine very simple and straightforward, so it is a bit different than most. I’m sure I’ll add a few modifications (I already added a water pan/heat diffuser) and eventually paint it black but for the most part, it is a finished product.

You’ll notice that the only thing sticking out of the side is a cheap thermometer that I had in the garage from one of the other pits long ago. Didn’t even put a handle on the top, that is what my Grill Armor gloves are for! I did buy some 4″ casters from Harbor Freight and mount on it for a couple of reasons. The obvious one, mobility, but more important I needed it off the ground because that is where I drilled my air intake hole.

I decided to go that route to keep the sides from having a bunch of pipe fittings and because one of the best grills I’ve ever had was the old favorite, Old Smokey Charcoal Grill. The only difference is that I didn’t put a lever to open and close the intake. Read Harry Soo’s take on draft control at his Slap Yo Daddy site to understand why I don’t think it needs one. To control the draft in my UDS, I put the same size 2 1/2″ hole in the drum lid for my exhaust and use refrigerator magnet stock to open and close it.

Okay, enough about my UDS experiment, let’s cook some St. Louis cut pork spare ribs!

First, I removed the membrane, excess fat, and the small rib bones at the end of the rack, then seasoned it with Bad Byron’s Butt Rub. I like this rub because it has a lower salt content than most commercial rubs.

Then I started the coals in a Weber chimney starter, about a third full. I use Kingsford Blue bag because it is very consistent and burns even and long.

I then put two chimney’s full of unlit coals in the fire basket, put two chunks of Applewood and one chunk of Mesquite, then dumped the hot coals on top. This is called the minion method or a version of it.

Then I put in the lower grate and my water pan/heat diffuser. The first couple of cooks I did on the UDS, I noticed that there was a 50F difference between my sidewall thermometer and the center of the top rack. So I found an old cast iron pot that had been sitting in the garden a few years, cleaned it up, added some screws to hold a bottom grate, and BAM! Just like that, the temperature evened out and I got the extra benefit of tons of moisture in the pit to help with the smoke ring! A good smoke ring looks great and is very hard to get in the Masterbuilt Electric Smoker I’ve been using.

After bringing the pit up to 225F and letting it level off for 20 minutes, I put the rack of ribs on, as well as the pieces I had removed in the trimming process. Those pieces do a couple of things. First, they render the fat out, letting it drop on the coals, adding flavor to the rack. Second, I can monitor the smoke process by tasting them at hourly intervals. It won’t necessarily help with this cook but it will let me know how the meat tastes with just the smoke, no seasonings. That way I can adjust the wood I use next time if I don’t like the flavor. That is why keeping a bbq notebook comes in handy!

After one hour:

After two hours:

After three hours:

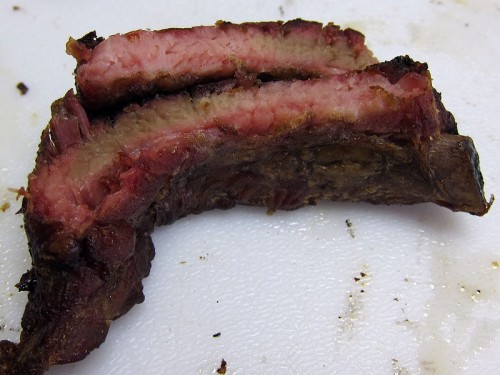

At this point, the bark was formed and it was time to wrapped the rack in foil. But first, this is one of those trimming pieces that I used to check the smoke ring:

Oh yeah. And it tasted great too! Let’s foil the ribs. Foiling helps tenderize as well as gives you a chance to add different flavors. I chose to use Parkay for velvety butter flavor, Sriracha sauce for heat, and some blue agave nectar for sweetness.

I put the rack on the foil meat side down and then put the same ingredients on the back side of the ribs.

And back on the pit we go!

At this point, you have to make a judgement call on how long to foil. The standard formula is 3-2-1, meaning three hours in the smoke, two hours in the foil, and one hour back on the pit. I knew from my trimmings that this rack was already getting tender, so I took it off and unwrapped it after 1.5 hours.

Whoo baby those things smelled good. I then basted the bottom of the rack with Jack Miller’s Cajun BBQ sauce, put the rack back on the pit, and basted the top with the same sauce.

That hatch chili is starting to smell good too. After another 45 minutes on the pit for the final baste, here is the finished product.

And finally, a middle rib:

I’m going to use that $210 I saved by not buying the Pit Barrel Cooker to buy some more meat to smoke.

Alright, now it’s your turn!

Have a great weekend, forget about politics, spend some time with your family and friends, and whatever you do, don’t let anyone steal your joy!

UPDATE 8-9-2014 7:45 am

The owner of the Pit Barrel Cooker company sends this in:

To: David Jennings

As per our conversation you said you would post my reply to the article you wrote about your experience with my company in my exact words. Below is my exact words. I had some trouble posting this to the comment section. For some reason it cut off after Sincerely,

As the owner and founder of the Pit Barrel Cooker Co. I can say that the two most important things to us is building a great product in the USA and providing customer service that is second to none. We have put a lot of hard work in to building our company to where it is today and truly living the American dream. To be able to serve my Country in combat, be lucky enough to come back home alive with all my limbs and start up a company producing an American made product that has become successful is as good as it gets for me. I rarely get involved with the rhetoric of articles such as this. A good customer came across this article and thought I should be aware. After reading the article I knew exactly who it was because we have only had one customer in the thousands of Pit Barrels sold that has asked for a refund. As stated our Company has a very hands on approach when it comes to customer service. Needless to say, I knew exactly who to call. I immediately apologized for anything we may have done wrong and went into great detail about our company and who we are as owners. I explained how our order process works and how hard we have worked to dig out of the back order situation we have experienced. I further explained the effort we make to get the product into our customers hands as fast as possible. I said to David Jennings that I was sure he is a responsible guy and would want to get his facts straight for his readers. He agreed but said he was only reporting his experience with our company. I’m OK with that and people have every right to do so. The problem I have with this article is David speculated on many things with no facts and is completely incorrect. If one considers themselves to be a professional that operates from a solid platform, the only responsible thing to do is report the facts responsibly and in this case it would be the facts of his experience with our company. The first issue I brought up was his speculation of what our cost is to manufacture and ship the Pit Barrel Cooker at a flat rate of $289.00 Now there is no doubt in my mind that the cooker David built costs $70.00 or less. That is very clear from the pictures. We take a lot of pride in producing a quality product made in the USA and shipped to your door for under $300.00. I told David that to manufacture our product we spend well over $100.00 per unit. David told me that if I could not manufacture the Pit Barrel Cooker for $70.00 then I did not know what I was doing running the company. I said I would be happy to go over all our cost and would really like to hear how he would go about building our product for $70.00 Shortly after this point David said to send him an email with all my complaints and said goodbye. Now I have seen a lot of people say a lot of things on Blogs and forums and to be honest the only ones that have negative things to say are people that speculate on what it would be like to own a Pit Barrel Cooker or how they can build one out of a steel drum that who knows what kind of chemical it could have held at one time. David has no clue as to what it costs to build our product. His wild guess of $70.00 to manufacture the product and the $210.00 he saved to spend on meat is incorrect as well. Charging a credit card before the product ships is a very common practice. As David stated in his article he received a phone call hours after he placed the order informing him of what the status was. This phone call was made from one of the owners of the company also thanking him for his business and letting him know the day it would ship. Stating that is bad business practice is also incorrect. Making statements that our company gave away seemingly hundreds of the things to cook off teams, BBQ forums and webmasters is also incorrect. We are a small business and could never afford to send hundreds of anything to all those people. We have sent a few units to a hand full of reviewers but not hundreds. That statement is also baseless and incorrect. Speculating that the reason we are back ordered or in David’s words how we take our time to ship our product could be due to cash flow problems is not only speculating but borderline slander with no base or fact.

People have to be careful what they read and more importantly what they write. I don’t claim to know everything and I’m far from perfect. When I make a mistake or do something wrong I own it and make it right. There are things I’m good at and things I’m not. One thing I’m very good at is making an outdoor cooker that brings friends and family together at an affordable price while providing customer service that is unheard of. My family and I are very grateful to all our loyal customers for their support and trust in our product and the people that stand behind it.

Sincerely,

Noah Glanville

President

Pit Barrel Cooker Co.

Proudly Made in the USA

www.pitbarrelcooker.com

303-249-9069

Make of that what you will. After my phone conversation and after reading that email from the owner, I’m very happy with my decision to cancel the order for one of his cookers. I have no doubt that you can cook good food on it – remember, it ain’t the cooker, it’s the cook. I’m not sure why he would want to say that my saving $210 by canceling the order and building the one above is incorrect, after all it is just simple math. I ordered one of his cookers for $289, I built an ugly but very effective one for less than $80, I saved $210 by doing that. As for my guess of roughly $70 to produce his product, I’m definitely in the ballpark on that one. Checking the cold rolled steel market over the past three years, the high is just under $0.42/lb. It takes roughly 29 lbs. of steel to make an 18 gauge 30 gallon drum, so the base cost of the steel for the drum is less than $11.50. Conversion cost to produce an unpainted drum with no closing ring will be somewhere in the $5 range, plus whatever profit the container company wants to make. Add in shipping, powder coating, punching five holes, 2 pieces of rebar, a fire basket, six horseshoes, a grate, and eight stainless hooks. You do the math. Nowhere in that post is anything that is even remotely close to slander. It’s one thing to be passionate about your company and product, it’s quite another to be outright belligerent on a phone call with someone who wrote about his experience with the company, not your product.

Have a great weekend folks and remember, don’t let anyone steal your joy.